Inkjet

Inkjet printing can be divided into two main processes, continuous inkjet and drop-on-demand.

With continuous inkjet, ink drops are continuously sprayed onto the print medium from the printer nozzles at high frequency. These drops are deflected by the currents at the electrode. This is how the print image is created on the paper or label.

With drop-on-demand, a drop is created first, this is triggered by an electrical signal. The advantage here is that the drop size can be controlled.

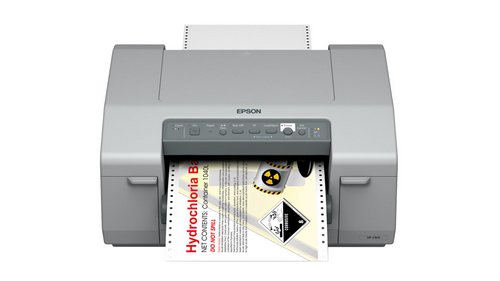

Inkjet printing is one of the digital printing processes and is very well suited for personalized printing in small print runs. The very good detail rendition gives you a good print result.

The large selection of inks, which all react differently, makes it difficult to achieve the optimum result with the existing printer. From experience, we have come to the conclusion that the somewhat expensive materials are more cost-effective in the end. High quality material can achieve a better result with less ink.

Do not hesitate to contact us, our team will be happy to help you.