Ihr Spezialist für Thermo- und Inkjetprodukte

Nakagawa Manufacturing Deutschland GmbH

- Wir bieten Ihnen umfangreiches Know-How

- Wir sind Ihr Lieferant für anwendungsspezifische Spezialpapiere

- Wir finden mit Ihnen gemeinsam Lösungen für komplexe Kundenanforderungen oder sind der Innovator für die Erschließung neuer Märkte

Unsere Produkte

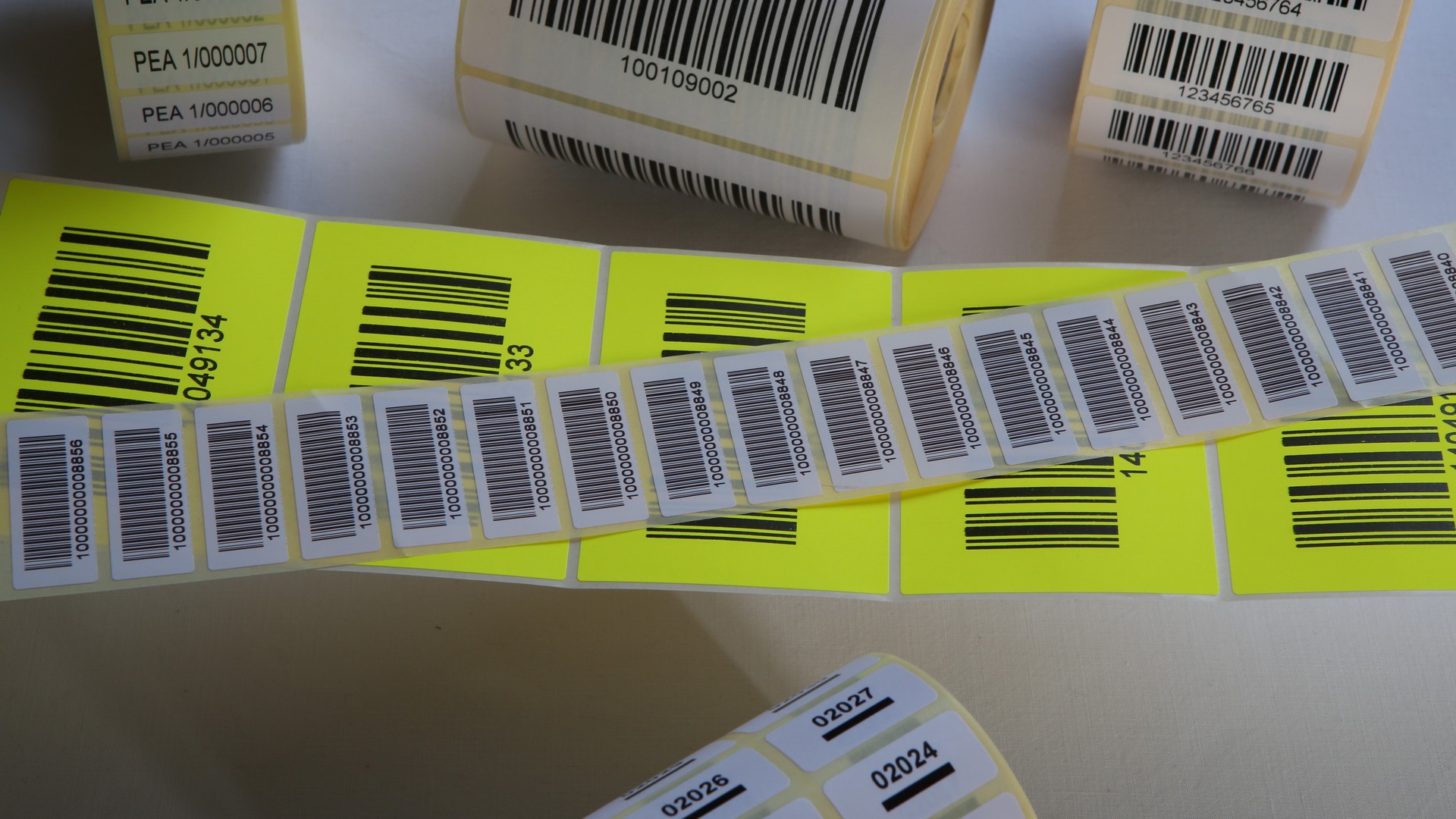

Etiketten

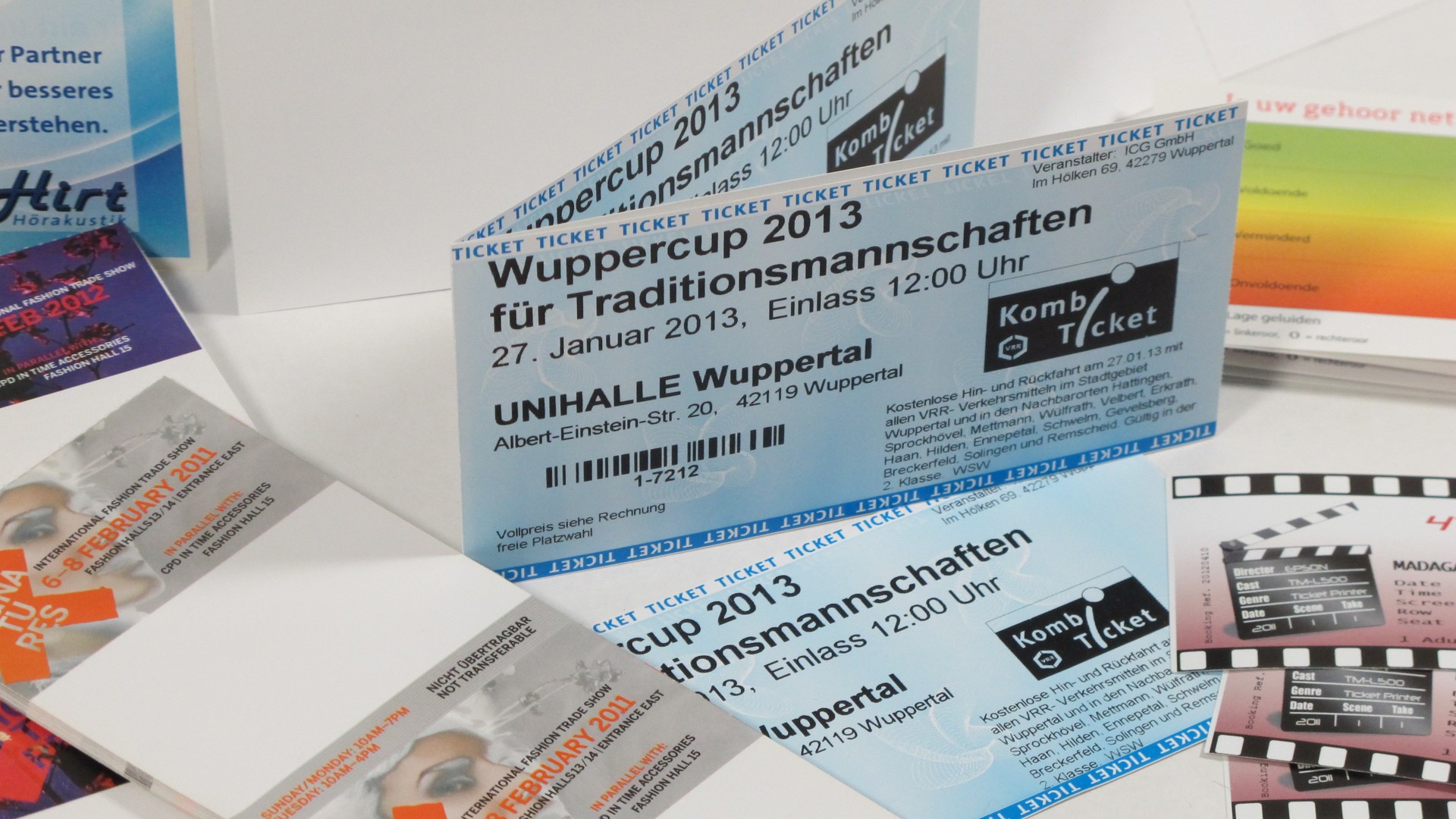

Tickets

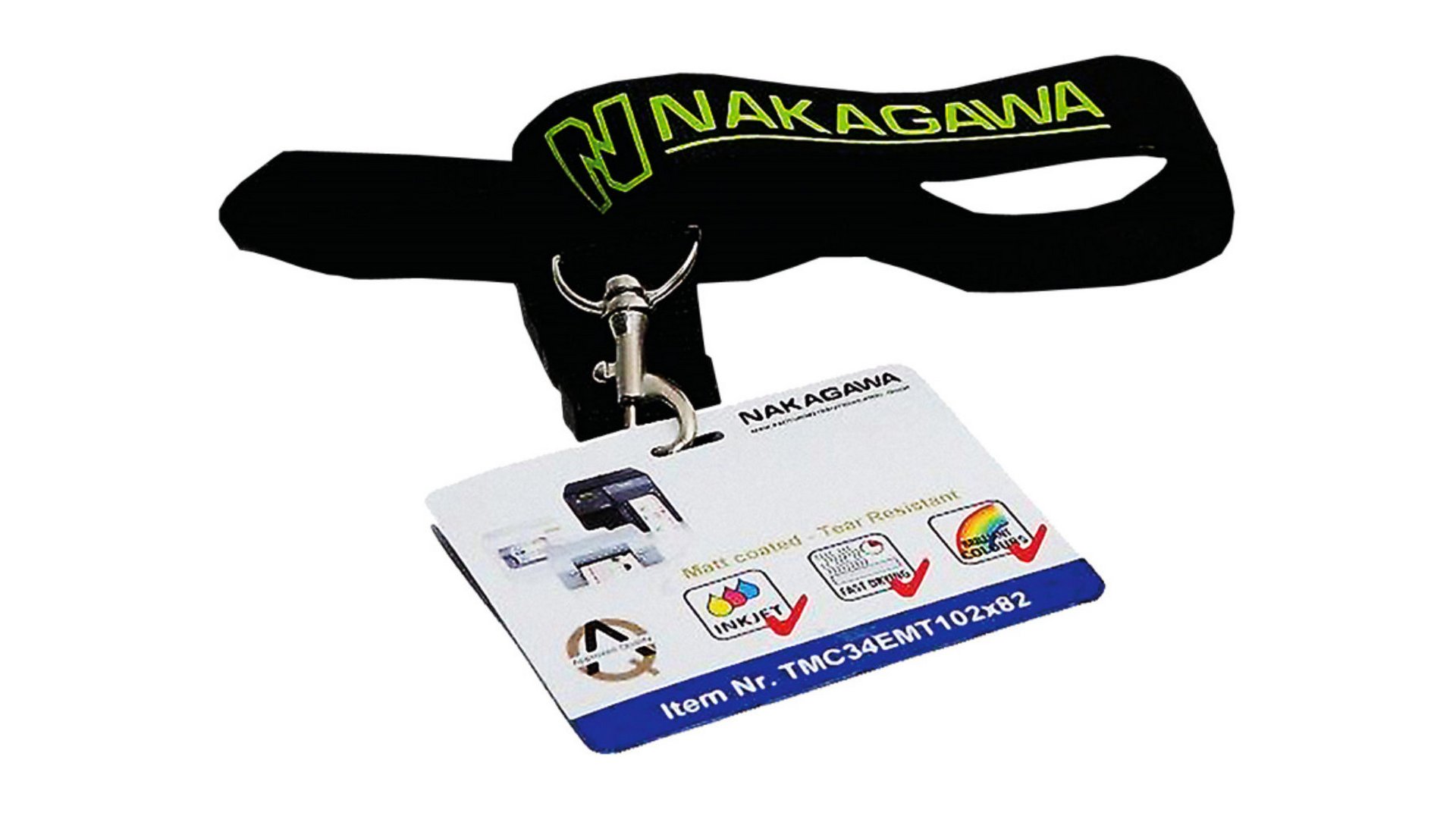

Besucherausweise

Kassenrollen

VIP – Bänder

Aktuelles

Zertifikate

NAKAGAWA Manufacturing Deutschland GmbH

Siemensring 66-68

47877 Willich

Telefon: +49 (0) 2154 8834 0

Fax: +49 (0) 2154 8834 66

Email: salessupport@nakagawa.de